Wear resistant composite steel plate

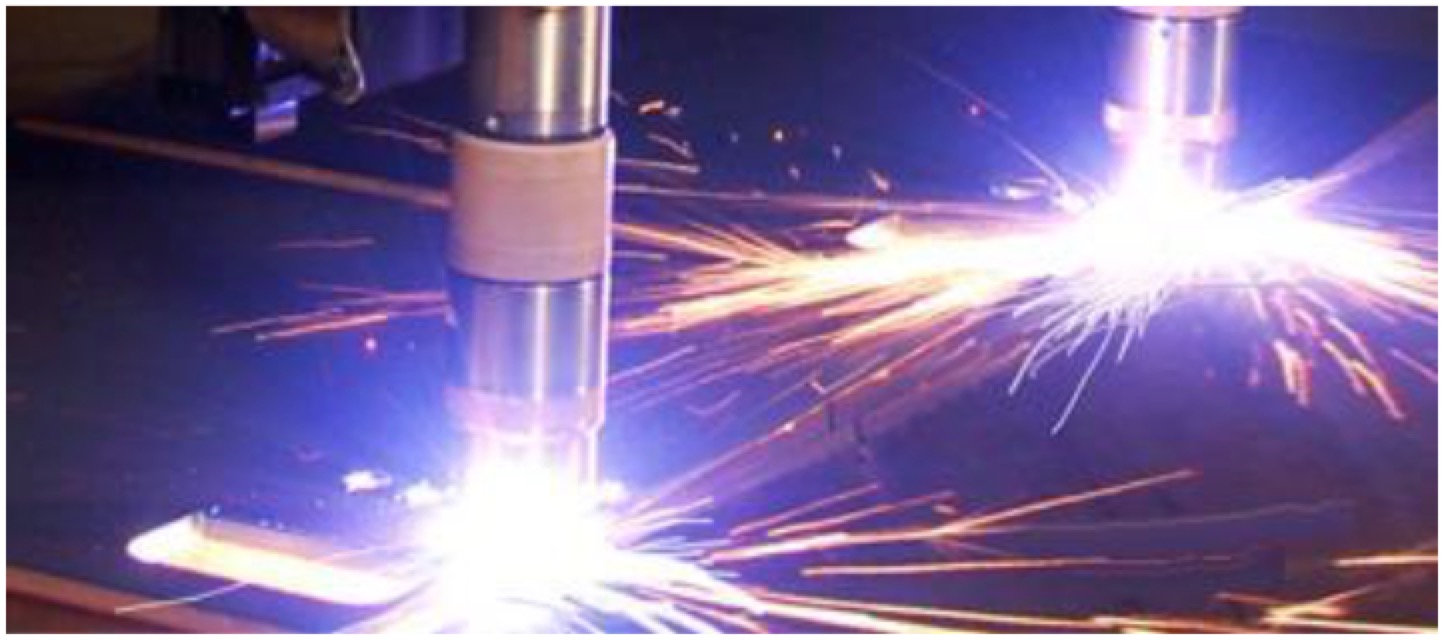

Chemical composition: Wear-resisting clad steel plate is a wear-resisting alloy coated with one or more layers of chromium carbide hard particles on medium and low carbon steel substrates, and some special elements are added to form carbides with special functions.

Microstructures: the volume fraction of Cr7C3 carbide in the metallographic structure of the wear-resistant layer is more than 50%.

Hardness: According to the thickness of wear-resistant layer, the surface hardness of wear-resistant alloy is HRC56-65, and the highest microhardness of chromium carbide is HV1800.

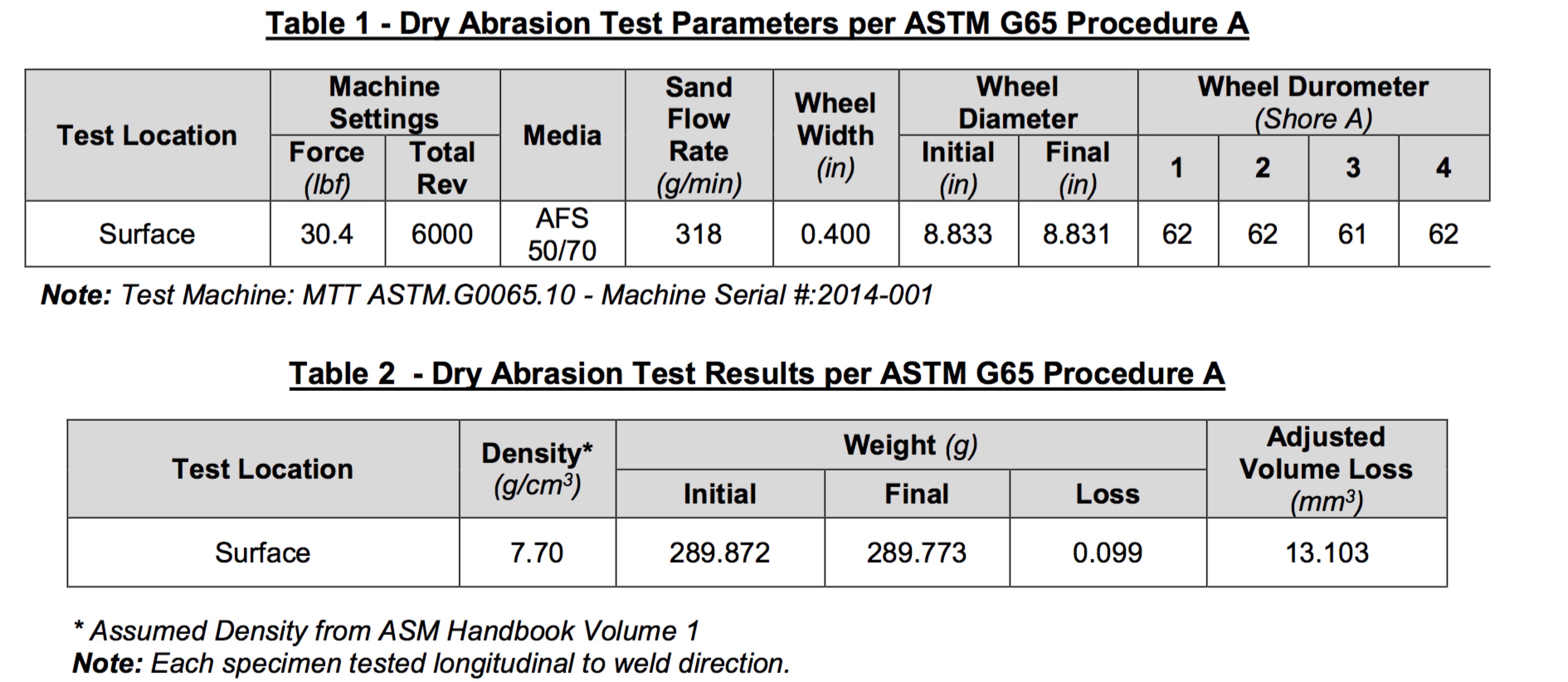

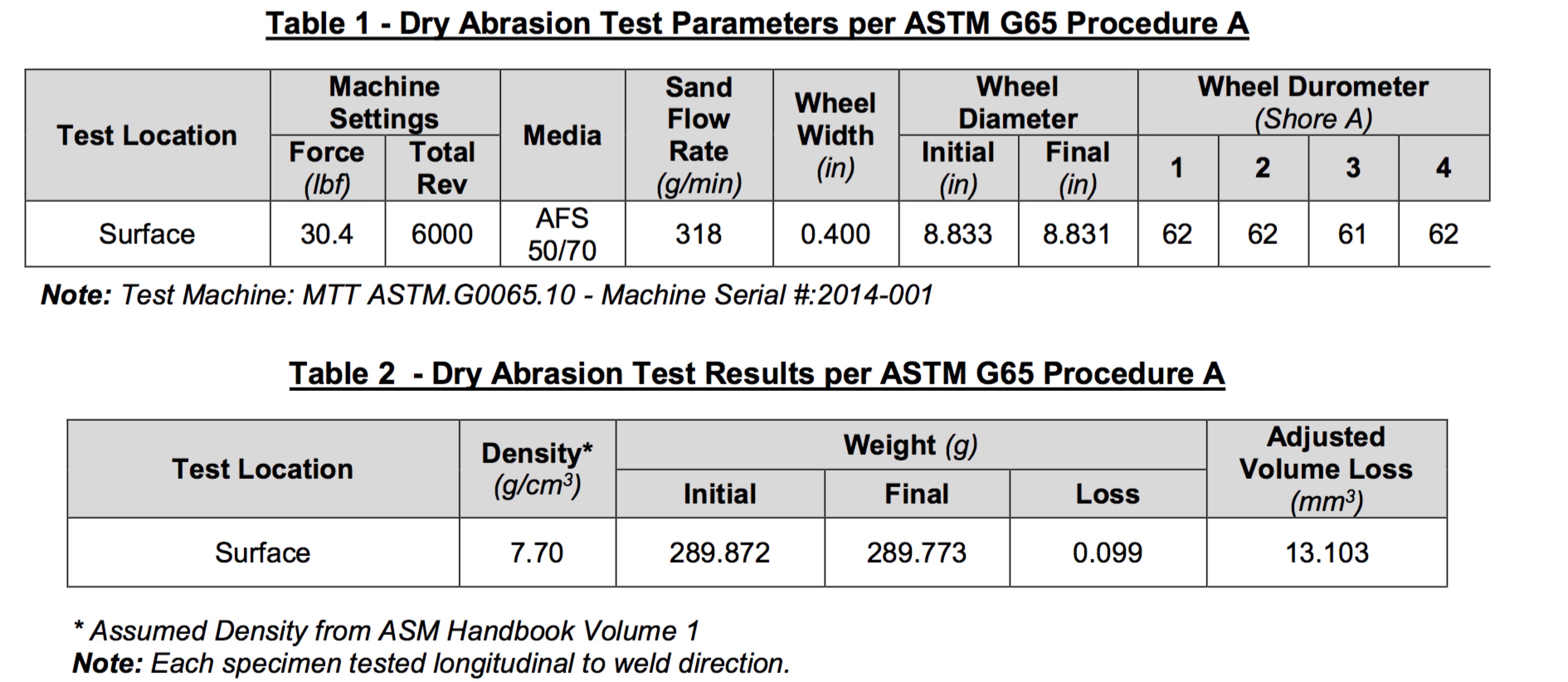

Wear resistance: The results of laboratory show that the wear resistance of Wodun clad steel sheet is 20 times that of low carbon steel and 8 times that of heat treated wear resistant steel. The surface wear of ASTM-G65A dry sand test and 75% deep wear test data show that the wear resistance of Wodun clad steel sheet is very high.

Flatness error: evenness is controlled at + 3mm/m.

Thickness error: the thickness of the wear resistant layer is uniform, and the thickness tolerance is 0-0. 5mm.

Main plate thickness

3+3\ 4+4v 5+5 6+4, 6+5v 6+6\ 6+8 8+4, 8+5\ 8+6\ 8+7 > 8+6\

10+4, 10+5, 10+6, 10+7, 10+8, 10+9, 10+10, 10+20

12+6,

14+10

16+10

18+1012+7, 12+8, 12+10, 12+11, 12+12, 12+18, 12+20

20+5, 20+6v 20+8, 20+10, 30+10, 40+10, 20+20, 20+25

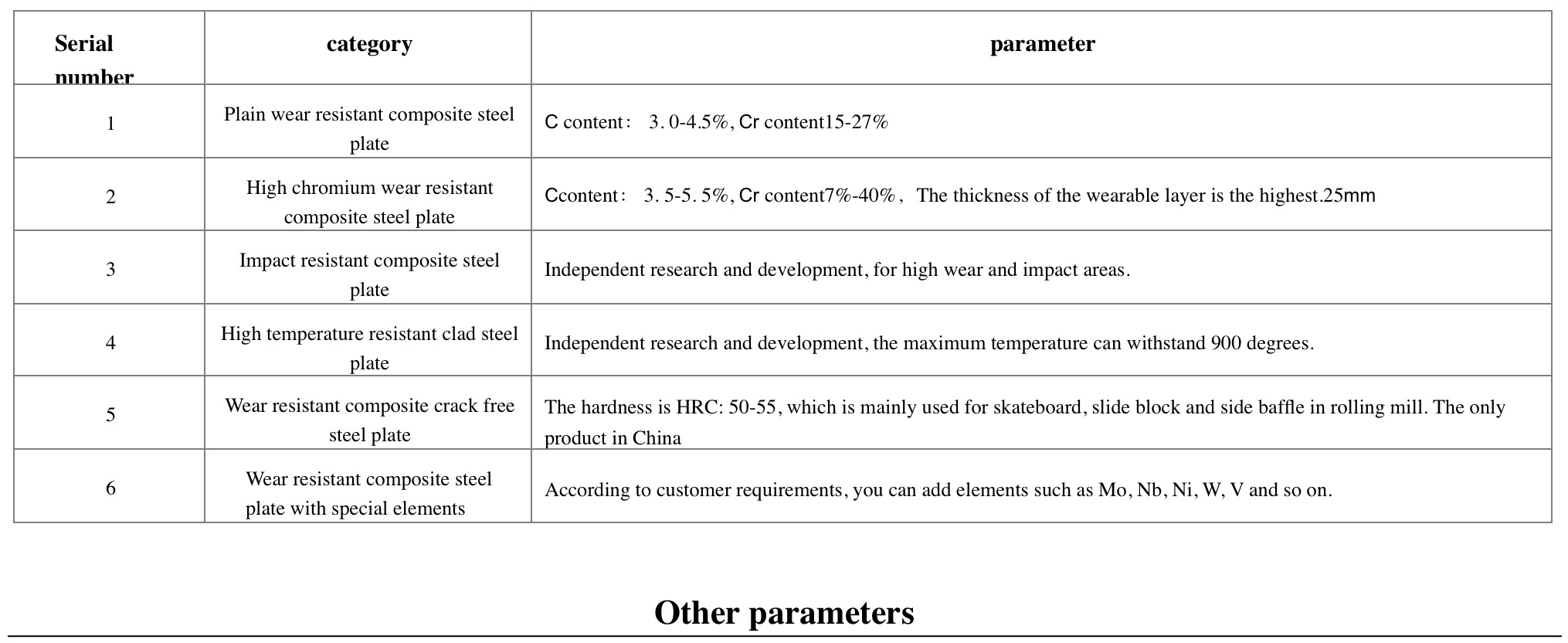

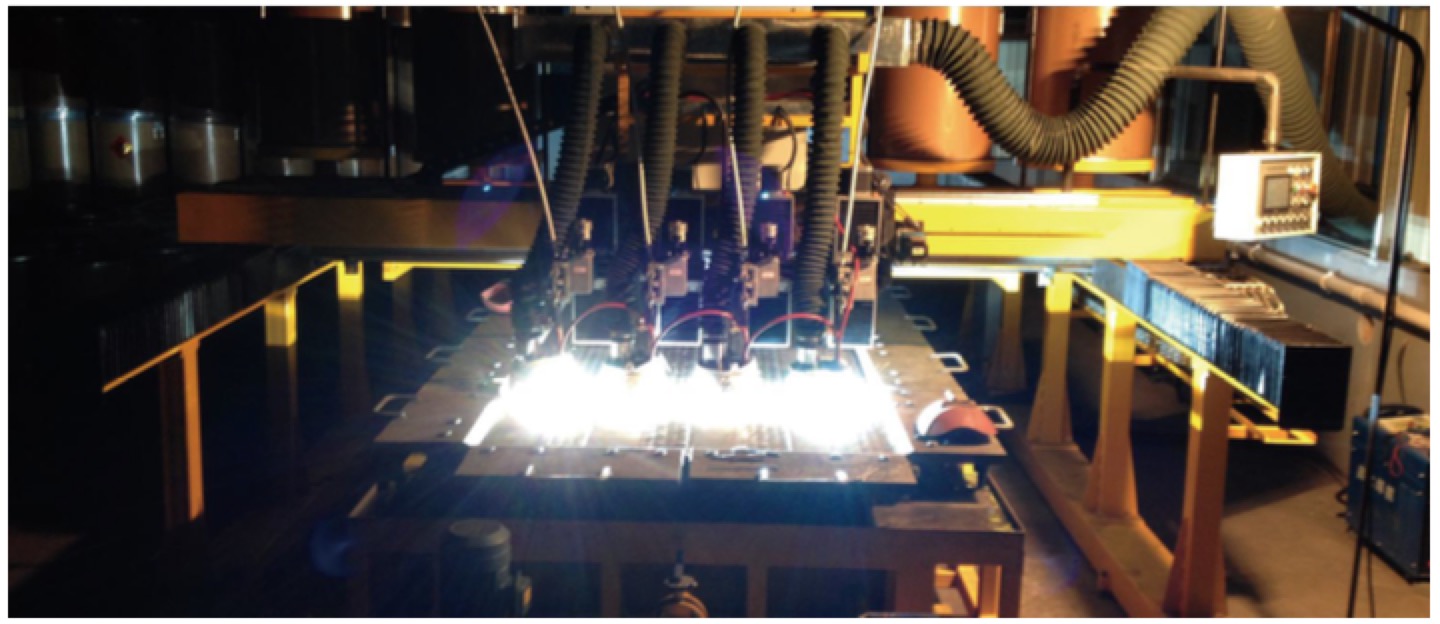

We can customize different sizes, specifications and thickness of special type of wear-resistant plate according to customer requirements, and according to the drawings provided by customers, cutting, bending, crimping, tailor-welded wear-resistant plate to become the required parts.

WD high chromium wear-resistant composite steel plate: used to withstand severe wear plate, such as wear-resistant pipe elbow liner sieve plate, etc.

High wear-resistant materials: wear-resistant alloy coated with one or more layers containing large amounts of chromium carbide hard particles on medium and low carbon steel substrates.

The volume fraction of Cr7C3 carbide in the metallographic structure of the wear-resistant layer is more than 50%.

Key points of high chromium wear resistant composite steel plate

Key points of high chromium wear resistant composite steel plate

1. The wear resistance of ASTM-G65A dry sand is 20 times that of low carbon steel and 8 times that of heat-treated wear-resistant steel. The wear resistance of ASTM-G65A dry sand is higher than that of low carbon steel.

2. flatness, tolerance of + 3mm/m thickness, wear resistant layer uniform, thickness tolerance 0~0.5mm.

3. hardness, the surface hardness of wear resistant alloy is HRC56~65, the highest hardness of chromium carbide is HV1800

ASTM wear test

Fusion strength of chromium carbide and substrate

ASTM wear test

Fusion strength of chromium carbide and substrate

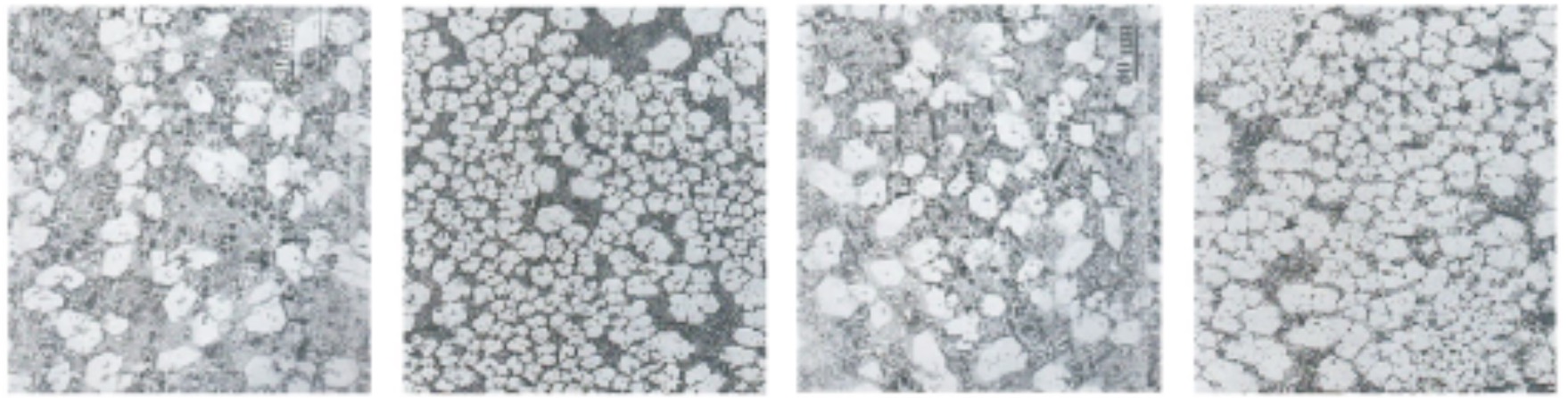

Microstructure of carbonized graphite

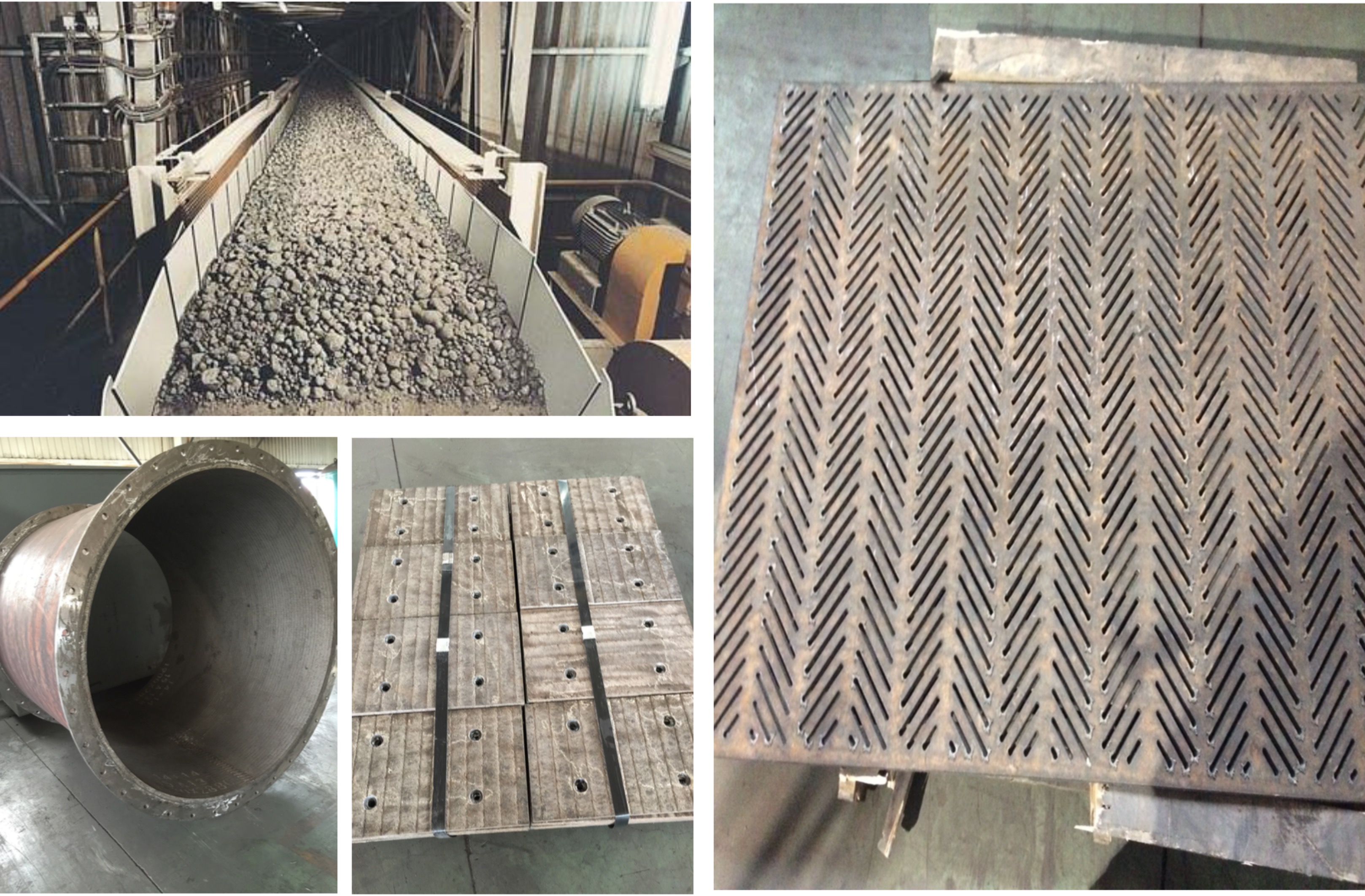

The wear resistance of wear-resistant composite steel sheet mainly depends on the hardness, shape, size, quantity and distribution of carbide particles.

It can be seen from the above diagram that the volume fraction of metallographic structure Cr7C3 carbide is more than 50%.

Bonding strength between wear resistant layer and substrate:

Wear resistant plates, clad steel plates and other wear-resistant layers and substrate are metallurgical structures, and the wear-resistant layer will penetrate into the substrate 0.8-1.8mm. The maximum metallurgical combination strength test data is 350Mpa.